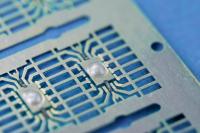

Potting & Encapsulation Compounds

Featuring outstanding electrical insulation properties, these systems are utilized in low, medium and high voltage applications and maintain superior thermal stability and chemical resistance. These systems offer protection against corrosion and crack resistance to ensure high performance.

Products shown on circuit board image: EP42HT-4AOMed Black, EP4EN-80

Learn more about potting compounds

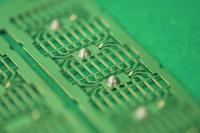

Die Attach Formulations

With die shear strength ranging from 20-42 kg-f, these systems are available in both electrically insulative or electrically conductive formulations. They meet the requirements for the many critical electronic devices manufactured for the medical, military, aerospace and other industries. These die attach adhesives are also available in one component heat curing formulations and as B-staged epoxy films.

Products shown on circuit board image: Supreme 3HTND-2DA, EP17HTS-DA, EP3HTSDA-2

Learn more about die attach formulations

Spin Coating UV Systems

Spin coatable UV curable systems are ideal for high precision optical component manufacturing applications. These one part compounds provide a thin film coating that allows the component to retain its original physical, transmission and reflective properties. Custom formulations can be engineered to protect components against harsh chemicals and abrasion.

Product shown on circuit board image: UV15

Learn more about spin coating UV systems

Underfill Compounds

This line of epoxy underfills offer superior stress reduction on solder joints as well as protection from moisture. They are available in both high and low viscosities as well as in snap curing and reworkable formulations.

Products shown on circuit board image: EP62-1LPSPMed, EP114

Learn more about underfill compounds

Glob Top Formulations

Ideal for the encapsulation of semiconductor chips and wire bonds, these glob top systems offer resistance to moisture, chemicals and contaminants. These thixotropic compounds offer low stress, low shrinkage upon curing and fast cure speeds.

Product shown on circuit board image: Supreme 3HTND-2CCM

Learn more about glob top formulations

Heat Sink Attachment

Compounds for heat sink attachment include one and two component epoxy and silicone systems featuring high thermal conductivity for heat dissipation. These materials contain special alumina,or aluminum nitride fillers to improve device reliability and help prevent overheating or premature component failure.

Product shown on circuit board image: Supreme 18TC

Compounds for Electronic Applications

|

EP42HT-4AOMed Black Thermally conductive, electrically insulative two part epoxy. Meets USP Class VI and ISO 10993-5 certifications. Cryogenically serviceable from 4K to +400F. NASA low outgassing aproved. Black in color. For bonding, sealing, coating and casting. |

|

EP4EN-80 One component, low viscosity epoxy that offers thermal conductivity, electrical insulation and a filler material with ultra small particle sizes. This imparts high mechanical strength properties, outstanding dimensional stability and low shrinkage upon curing. |

|

Supreme 3HTND-2DA One component, fast curing die attach adhesive. Excellent die shear strength. Serviceable from -100°F to +400°F. Low ionics. Superior thermal conductivity and electrical insulation properties. Dispenses smoothly without tailing or bleed out. Cures in 5-10 minutes at 150°C. NASA low outgassing approved. Available in syringes. Well suited for automatic dispensing. Performed well in 85°C/85% RH testing. |

|

EP17HTS-DA Silver filled, one part, no mix, die attach epoxy with electrical conductivity and high temperature resistance. It is a silver filled system. This specialty formulation maintains a high Tg of 140-150°C and passes MIL-STD-883J thermal stability requirements at 200°C. |

|

EP3HTSDA-2 Silver filled electrically conductive epoxy has a rapid cure speed. Low volume resistivity and high temperature resistance. Superior bond strength. Thermally conductive with incredibly low thermal resistance. Smooth paste, consistency. Available in syringes that are compatible with various types of automatic dispensers or manual dispensing. Serviceable from -80°F to +450°F. |

|

UV15 Low viscosity, rigid UV curable system with superb thermal stability. Also capable of spin coating. Outstanding optical clarity. High bond strength. Serviceable from -80°F to +350°F. |

|

EP62-1LPSPMed Ultra low viscosity, toughened epoxy with superior electrical insulation properties. Thermal stability. Exceptional sterilization resistance. Long working life. Low exotherm. Passes USP Class VI and ISO 10993-5 requirements. Serviceable from -150°F to +400°F. |

|

EP114 Two component nanosilica filled epoxy for potting, coating and sealing. Optically clear. Low shrinkage. Superior electrical insulation properties. Toughened system. Successfully tested for 1,000 hours 85°C/85% RH. Serviceable from -100°F to +450°F. |

|

Supreme 3HTND-2CCM Toughened epoxy system for bonding, sealing, coating, encapsulation, glob topping. Requires no mixing. Rapid heat curing Passes NASA low outgassing testing. Transfers heat efficiently. Ideal rheology and flow for multiple applications. Stellar electrical insulation properties. Serviceable from -100°F to +400°F. |

|

|

Supreme 18TC single component epoxy adhesive features unmatched heat transfer properties. Capable of being applied in bond lines as thin as 10-15 microns. Low coefficient of thermal expansion. Meets NASA low outgassing specifications. Low shrinkage upon curing Operating temperature is 4k to +400°F. |