Elongation is a measure of ductility of a material. It is expressed as a percentage, and it is the ratio of change in axial length with the application of a tensile force to the original length of the specimen. It ultimately expresses how much a material can be stretched or deformed before it breaks. Materials with a higher elongation at break also have a higher ductility and higher flexibility.

To determine the elongation of our products, Master Bond performs testing based on ASTM D638 - 14 Standard Test Method for Tensile Properties of Plastics. In addition to elongation, this valuable test measures properties like tensile strength and tensile modulus.

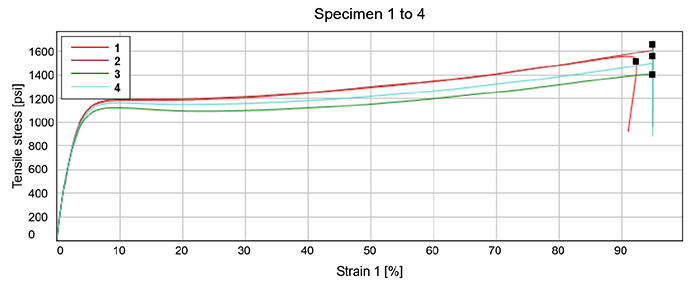

The graph below shows a typical stress–strain curve for one of our high elongation products. As shown on the graph, four different specimens are tested, and the average value of the strain at break is taken as the elongation of the material.

Master Bond offers a variety of products with different elongations. These values vary from as low as a few percent or less for very rigid epoxy systems to more than 150% for flexible products like silicones.

Materials with higher elongation can be useful in applications that also require a lower durometer, lower hardness, and less stress. Whereas materials with lower elongation can be used in applications that require a lower CTE, lower shrinkage, and higher dimensional stability.

Our Most Popular High Elongation Systems

|

EP29LPHE Low viscosity epoxy for large potting/encapsulation applications. Low modulus, high elongation. Long working life. Exceptionally low shrinkage upon cure. Impressive optical clarity. Low exotherm. Serviceable from -60°F to +250°F. |

|

EP21TDC-4ND Smooth paste epoxy adhesive. High flexibility. Elongatio >200%. Impressive resistance to mechanical vibration and shock. Outstanding adhesion to rubbers such as SBR, nitrile, neoprene. T-peel strength >30 pli. Serviceable from -100°F to +250°F. |

|

EP51FL-1ND-2 Flexible epoxy adhesive has rapid set up time and cure speed. High peel strength and elongation. Withstands mechanical shock and vibration. Resists thermal cycling. Superb electrical insulation properties. Service operating temperature range from -100°F to +250°F. |

|

MasterSil 705 Translucent flowable paste for bonding, sealing, coating, formed-in-place gaskets. Cures upon exposure to atmospheric moisture. Serviceable from -75°F to 400°F. Available in tubes, cartridges. |